In gasket manufacturing, moving from a one-off prototype to full-scale production is where real expertise shows. A design that performs perfectly in testing must be reproduced multiple times with the same accuracy, material integrity, and reliability. For engineers and procurement teams alike, consistency at scale is just as critical as initial performance.

At Dobson Gaskets, we specialise in bridging this gap. Our production processes are built to ensure that what works in prototype works just as well in volume, without compromise.

From Design to Manufacture: The Gasket Production Journey

Every gasket begins with a design intent: sealing performance, operating conditions, material compatibility, and dimensional tolerances. Translating these requirements into a manufacturable product involves several key stages:

- Design & Specification

CAD drawings, material selection, and tolerance definitions establish the foundation. Early design decisions influence not only performance, but also the most appropriate production method. - Prototyping & Validation

Initial prototypes confirm fit, function, and sealing effectiveness. This stage often involves rapid, flexible cutting methods to allow fast iteration. - Process Selection for Scale

As volumes increase, the focus shifts to repeatability, efficiency, and cost control, while maintaining the same quality standards validated during prototyping. - Production & Quality Control

Controlled processes, calibrated equipment, and robust inspection systems ensure every gasket meets specification.

The challenge lies in maintaining absolute consistency as production scales. Different manufacturing methods each bring their own considerations.

Gasket design, prototyping and quality control are key to maintaining consistency at scale.

Managing Consistency Across Key Production Methods

Knife Table / CNC Router Cutting

Best for: Prototypes, low-to-medium volumes, softer gasket materials

Key challenges at scale: Tool wear, material movement, edge consistency

Knife tables and CNC routers offer exceptional flexibility and fast turnaround, making them ideal for prototyping and short production runs. However, as volumes increase, blade wear and material variability can introduce dimensional drift. Our approach to avoiding these issues in production includes:

- Scheduled blade changes and tool condition monitoring

- Optimised nesting to minimise material stress

- Controlled material handling to prevent distortion

These measures ensure repeatable accuracy even across extended production runs.

Water Jet Cutting

Best for: Medium volumes, thicker or composite materials

Key challenges at scale: Kerf variation, taper, and edge finish

Water jet cutting provides cold cutting with no heat-affected zone, preserving material properties. At higher volumes, maintaining consistent edge quality and dimensional accuracy requires precise process control. To counter these issues in production, our processes include:

- Fine-tuned pressure and feed rates per material

- Regular nozzle and abrasive maintenance

- Process validation to minimise taper

This delivers clean, accurate parts that remain consistent from first piece to last.

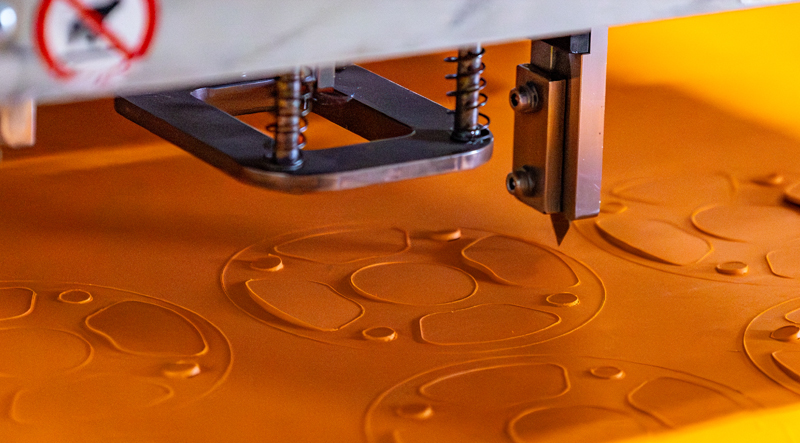

Laser Cutting

Best for: High precision, thin materials, medium-to-high volumes

Key challenges at scale: Heat effects, material sensitivity

Laser cutting excels at producing highly accurate gaskets at speed. However, heat-affected edges and material compatibility must be carefully managed when scaling production. Our operatives maintain consistency in production by:

- Using material-specific laser settings

- Continuous monitoring of cut quality

- Design optimisation to reduce thermal stress

The result is tight tolerances and excellent repeatability without compromising material integrity.

Punch Press / Die Cutting

Best for: High-volume production

Key challenges at scale: Tooling wear, upfront investment

For large production runs, punch pressing and die cutting offer unmatched speed and unit cost efficiency. Consistency depends entirely on tooling quality and maintenance. To maintain consistent accuracy during production, our processes feature:

- Precision-engineered tooling designed for longevity

- Preventative maintenance schedules

- In-process inspection to detect wear before it impacts quality

This ensures thousands of identical gaskets can be produced with confidence.

Gasket manufacturing methods such as automatic presses, laser cutting, and water jet cutting each bring unique challenges to producing at scale.

Why Consistency at Scale Matters

In real-world applications, gasket failure isn’t an option. Inconsistent dimensions, surface finish, or material behaviour can lead to leaks, downtime, and costly failures. That’s why scalable quality isn’t just about production, it’s about risk reduction.

By selecting the right manufacturing method and applying disciplined process control, Dobson Gaskets ensures:

- Reliable sealing performance

- Predictable lead times

- Reduced waste and rework

- Confidence in long-term supply

Dobson Gaskets: Expertise from Prototype to Production

What sets Dobson Gaskets apart is not just our range of manufacturing capabilities but our understanding of how to scale them effectively. We work closely with customers from initial design through to full production, advising on materials, tolerances, and processes that support long-term consistency.

Whether you need a rapid prototype, a short-run specialist gasket, or high-volume production to exacting standards, our expertise ensures your gasket performs the same way every time.

Talk to Our Experienced Technical Team

From prototype to production, Dobson Gaskets delivers quality and consistency at scale.